Không có sản phẩm trong giỏ hàng!

How to Make 3D Prints Watertight

- Abdulrahman Alhamed

- 23 Jul 2023

- Tutorial

- Beginner

- 636

While 3D printing allows us to create intricate designs and prototypes with ease, one common challenge faced by users is ensuring that 3D prints are watertight. A watertight 3D print is essential for functional parts, outdoor use, and applications where water resistance is required. In this article, we will explore effective techniques to make your 3D prints watertight.

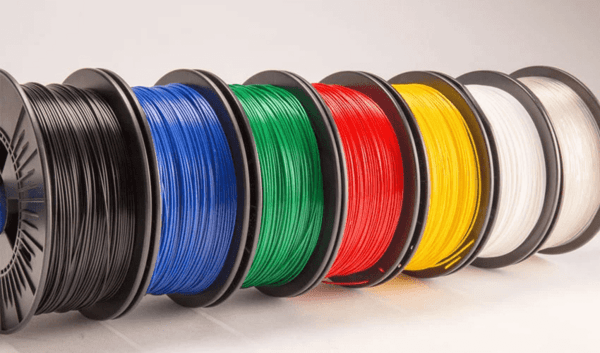

Material Selection

Opting for materials known for their water resistance, such as ABS, ASA, or PETG, is crucial in ensuring the successful creation of watertight 3D prints. These materials have demonstrated exceptional performance in moist and humid environments, making them ideal choices for applications where water resistance is essential.

These materials provide a strong foundation for achieving watertight 3D prints due to their inherent properties, which reduce the risk of water seepage through the print's layers. However, it is essential to note that achieving complete water resistance also depends on the printer settings, design, and post-processing techniques applied.

Adjust Print Settings

Adjusting print settings is a crucial step in achieving watertight 3D prints, as it directly impacts the print's surface quality, strength, and overall resilience to water infiltration. Here are some key factors to consider when fine-tuning print settings:

- Layer Height: The layer height directly affects the surface finish and overall strength of the 3D print. To enhance water resistance, consider using a smaller layer height. Smaller layers result in smoother surfaces and stronger layer adhesion, minimizing the chances of water seeping through gaps.

- Infill: Increasing the infill percentage can significantly improve the strength and water resistance of 3D prints. A higher infill provides better internal support and reduces the risk of cracks or leaks in the model.

- Temperature: Proper nozzle and bed temperatures are crucial for consistent layer adhesion and print quality. Adjust the temperature settings based on the material being used, as specified by the manufacturer, to ensure optimal performance and water resistance.

Post-Processing

Post-processing plays a crucial role in achieving watertight 3D prints by addressing imperfections and enhancing the print's surface integrity. Here are key post-processing steps to consider:

- Inspection: After printing, carefully inspect the model for any imperfections, gaps, or holes. Pay special attention to areas where layers may not have adhered properly.

- Sealing: Use appropriate fillers such as epoxy resin, putty, or super glue to seal any gaps or holes found during the inspection. Smooth the surface using sandpaper to ensure a seamless finish.

- Solvent Smoothing (for specific materials): For materials like ABS, consider using acetone vapor smoothing. Place the ABS print in an airtight container with a small amount of acetone to create a smooth surface and improve water resistance.

Protective Coatings and Sealants

Protective coatings and sealants are essential final steps in ensuring the longevity and water resistance of 3D prints. Here's a closer look at different types of coatings and sealants and how they enhance the performance of 3D prints:

- Polyurethane Spray: Polyurethane spray creates a protective layer over the print, making it more water-resistant and durable. Apply the spray evenly over the surface and allow it to dry thoroughly.

- Silicone Sealants: Silicone sealants are ideal for sealing gaps and seams in 3D prints. Use a fine applicator or brush to apply the sealant precisely where needed.

- Epoxy Coatings: Epoxy coatings provide an additional layer of protection against water infiltration. Apply the epoxy using a brush or roller, ensuring complete coverage.

Conclusion

Achieving watertight 3D prints requires a systematic approach, starting with the right material selection and proper print settings. Pay close attention to layer height, infill, and temperature to optimize water resistance. Thorough post-processing, including inspection, sealing, and solvent smoothing, further enhances the print's ability to withstand water exposure.

Applying protective coatings and sealants as a final step adds an extra layer of protection, ensuring that your 3D prints are resilient and capable of withstanding challenging environments. By following these steps and techniques, you can create water-resistant 3D prints suitable for a wide range of applications, from functional prototypes to outdoor structures.

International

International Singapore

Singapore Malaysia

Malaysia Thailand

Thailand Vietnam

Vietnam